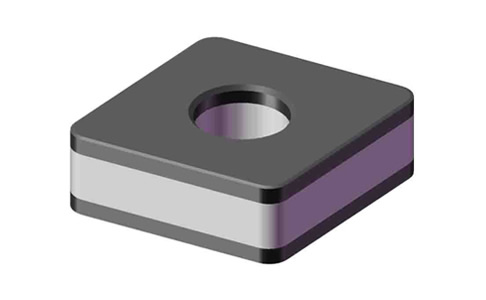

The SNGA series integral composite PCBN blade is directly composite under high temperature and ultra-high pressure environments, with advantages such as ultra thick composite layer (1-2mm) and high density. One side of the blade is made of PCBN material with a central hole positioning, widely used for semi precision machining and precision machining of gray cast iron, wear-resistant cast iron, heat-resistant alloys, and quenched and hardened steel.

The overall composite PCBN tool is capable of handling harsh machining environments, with further increased cutting depth, better impact resistance, more cutting edges, higher temperature resistance, and no desoldering, exhibiting excellent cutting performance. The bonding strength between the composite layer and the substrate is high, suitable for cutting depths of 0-5mm, continuous and light intermittent cutting.

CBN tool material grade