The SN series CBN integral sintered blade (referred to as CBN blade) has a square shape and various models and specifications. Under the high temperature and high pressure of the six sided hydraulic press, sintering synthesis has extremely strong wear resistance, heat resistance, and chemical stability. It can efficiently turn cast iron brake discs, cast iron brake drums, boron cast iron cylinder liners, cast iron clutch pressure plates and other automotive components, achieving the goal of replacing grinding with turning. The SN series CBN blades are matched with 45 °, 75 °, 83 ° outer circle turning tool holders, and come in three types: R, L, and N.

The high hardness workpieces of shafts and gears mainly made of HRC55-65 quenched steel are difficult to machine. When turning such parts, Zhengzhou Bote CBN inserts can be used, which not only saves the grinding process and replaces it with turning, but also improves productivity, shortens processing time, and reduces production costs. CBN blades belong to reversible multi blade blades, allowing multiple processes to be performed in one clamping, reducing the number of tool changes. From the perspective of environmental protection, CBN blades are most suitable for high-speed dry cutting without coolant, reducing environmental pollution. The chips can be well recycled and processed more simply and conveniently.

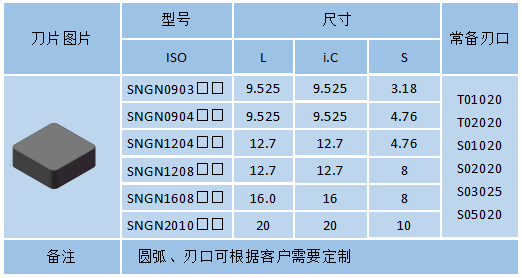

Specification and model: